Hello Cold Chain Colleagues,

2024 is off to an incredible start, and we have already seen some fantastic accomplishments.

Our journey continues with a deep commitment to excellence and sustainability, and I’m excited to share some key highlights with you.

Our journey continues with a deep commitment to excellence and sustainability, and I’m excited to share some key highlights with you.

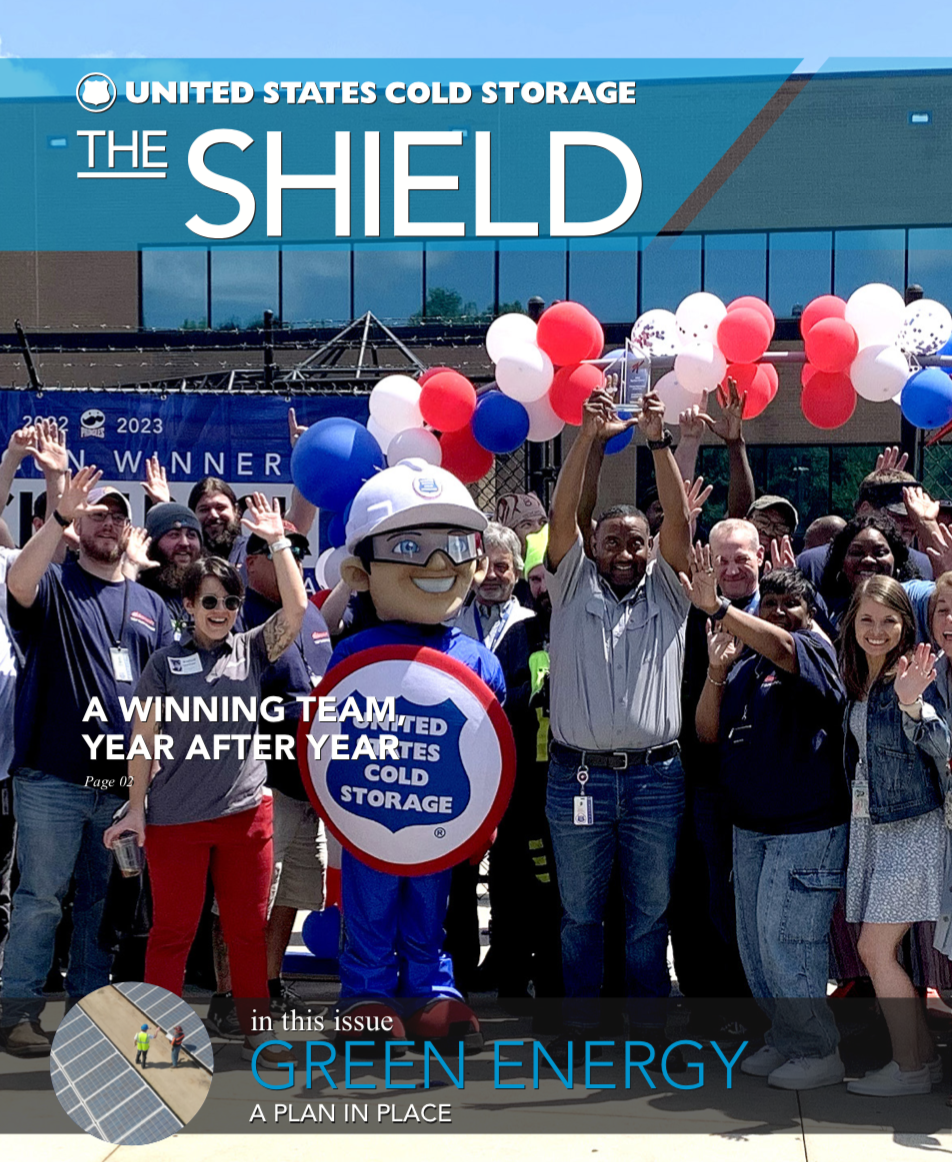

First, I want to extend a heartfelt congratulations to the team in McDonough, GA for winning Kellanova’s Top Gun award for the second year in a row (formerly Kellogg’s). This achievement underscores our dedication to customer service, operational excellence, and the great partnership we have with Kellanova for over 40 years.

As they have grown, we have grown. We appreciate that they foster such service focused initiatives, which drive us to continuously improve, evolve and excel. It’s through competitions like Top Gun that our team remains motivated and focused on meeting our customers’ key performance indicators.

Second, our dedication to sustainability has reached new heights with the establishment of two highly important targets. Our board has recently approved our ambitious goal to achieve 100% renewable energy by 2030, alongside our commitment to being SBTi (science based target initiatives) compliant, which means reducing 95% of our scope one and two carbon emissions by 2032.

A huge thank you to our sustainability team, led by Dan Postlewaite, with Sara Cook’s exceptional ability to translate complex sustainability topics into achievable goals. Their efforts have made it possible to develop a clear and comprehensive roadmap to reach our renewable energy goals. This plan includes a combination of energy reduction, solar arrays, green energy tariffs, and purchase power agreements for renewable energy. We are confident that these initiatives will not only lead the industry but also resonate with our customers, reinforcing our position as a sustainability leader.

In line with our ambitious sustainability journey, we are making substantial investments in modernizing our infrastructure to enhance energy efficiency. Over the next three years, we will invest $25 to $30 million in modernizing our blast freezers, expecting a 10% reduction in related power consumption. Additionally, we are incorporating AI and machine learning into our refrigeration control systems to achieve a further 10% efficiency gain overall across our network.

These improvements are critical steps toward our sustainability goals and will significantly reduce our environmental impact. We have fully vetted a green energy plan that outlines our pathway to 100% renewable power by 2030. This plan includes energy reduction, on-site solar generation, renewable energy purchase agreements, and green tariffs.

These are all significant sustainability milestones. The board, the sustainability team, and I are incredibly excited about our journey forward.

In closing, I want to reiterate how inspired I am by the dedication and impact of our Cold Crew. Each day, you prove what it means to be the Best in Cold. It’s a great time to be in the cold chain industry, and it’s an even greater time to be at USCS.

Together, we are shaping the future of cold storage with innovation, a Best in Service commitment, and sustainability at the forefront.

All the best,

Larry Alderfer | President & CEO

They’re Gr-r-reat!

USCS McDonough 1 earns “Top Gun” award for second straight year.

Perhaps it’s true when they say that the more things change, the more they stay the same.

What changed? Last October saw The Kellogg Company spin-off its cereal business into another publically traded unit, the WK Kellogg Company. In turn, a newly formed Kellanova, Chicago, emerged with a portfolio of the company’s snack brands (including Pringles, Pop-Tarts, Cheez-It, RX Bar) and its popular frozen businesses (including Eggo and Morningstar).

What stayed the same? Kellanova kept its long-standing “Top Gun” program to reward 02 outstanding third-party warehouse supplier partners. Interestingly enough, USCS McDonough 1 (Atlanta) also repeated as the Top Gun honoree. After winning for its 2022 performance, McDonough 1 led all third party warehouses in meeting or exceeding Kellanova’s Top Gun performance criteria (see below) in 2023.

“We found out about our award during a daily conference call with Kellanova,” says Dedric Thomas, USCS McDonough 1 General Manager. “Our team—as a whole— really did an outstanding job. Not only am I referring to team members on the floor but also everyone in our Inventory Department through Customer Service. I was impressed about our turn times and inventory accuracy. It was good to see how the team was able to overcome any and all challenges involving the sheer number of daily inbound and outbound shipments.

This is truly a team win.” Also excited to celebrate that team win were members of Kellanova’s supply chain group, including Kandi Crowe, Senior Director of Distribution. Crowe and Kellanova officials visited McDonough to announce the award and present prizes. Awards included televisions, grills, drill sets, Amazon gift certificates and even paid vacation days. The event included a catered lunch and even ended with a fireworks show.

“The USCS McDonough location continues to be a ‘Top Gun’ powerhouse in 2023! With the win in 2022 this could have driven the site to be complacent, but they never took their foot off the pedal and continued to show they are the best,” says Crowe. “Dedric, Thomas, Lisa, and Jessie reflect this ‘Culture of Best’ every day with the Kellanova Team. I know they will continue to strive to be the best in 2024 and beyond.”

For his part, Dedric is quite appreciative of the Kellanova relationship. “They’re the only account that even recognizes our service,” he notes. “They also provide constant feedback and always ask is there anything that we need from them.”

1. TRIR – Goal of 0 Quality

2. Holds not Processed – Goal of 0

3. Warehouse Cuts (Impact to Fill Rate) – Goal of 0.42% (based on cases cut vs cases shipped)

4. On Time Loading – Goal of 89%

5. Warehouse Damage – Goal of 0.04% (based on cases damaged at the DC vs total on hand)

6. Net Inventory Variance (Absolute Value) – Goal of 0.04%

7. OS&D – Goal of 0.05%

How I Help Feed America

Question connects people to purpose, USCS’s supply chain role to serve America.

With approximately 4,000 employees and a nationwide network of 39 coast-to-coast locations, United States Cold Storage handles the food served every day at America’s table. And that includes everything from ice cream to entrées and snacks to seafood.

At US Cold, members of the “Cold Crew” understand the vital role they play in safeguarding temperature-sensitive products to ensure quality and safety. To gain insights into each employee’s sense of purpose in this process, USCS asked a group of employees how their jobs contribute to feeding America. Here are some of their responses:

Plan Your Work, Work Your Plan

USCS’s new Green Energy Plan sets industry-leading example for new strategies, technologies.

There’s an adage that applies to every facet of life and logistics: plan your work and work your plan. When it comes to sustainability, this year finds the USCS Sustainable Engineering team making transparent and trackable plans all the way to 2050.

The group’s new Green Energy Plan (GEP) not only lays out energy and emission reduction targets but also critical action steps across every facet of business. “Our GEP is a milestone achievement,” says Sara Cook, Sustainable Development Manager. “We consolidated the collective expertise of internal functions, staff and external sources to develop a forecasting tool.

It predicts the energy needs, costs of renewable electricity solutions, and associated greenhouse gas (GHG) reductions for each solution. Our forecasting is dynamic and will even incorporate illustrated decision points—over time—for the business to consider.

Overall, the GEP connects clearly into USCS’s SMART targets for Climate and supports USCS’s net zero strategy.” Rob Moore is a USCS Project Engineer working with solar and energy technologies. “I’m particularly proud of our ambitious plans to pursue on-site solar,” he says. “As an organization, it would have been very easy for us to choose easier mechanisms of decarbonization—such as purchasing offsets to reduce our carbon footprint.

The GEP outlines our pathway to leveraging all these solutions in a way that enables company resilience, growth, and performance. This is all in keeping with USCS’s ‘Best-in-Cold’ approach.”

Sara Cook

Sustainable Development Manager

That certainly would have been the path of least resistance. However, we’ve decided to build and operate our own on-site, renewable energy sources, which have environmental benefits beyond what a purchased carbon offset could achieve.”

USCS’s goals are to:

1. Achieve 100% renewable electricity (RE) consumption by 2030

2. 95% reduction in Scope 1 and 2 GHG emissions by 2032 (from a 2022 base year)

3. Net zero greenhouse gas emissions by 2050.

Cook adds USCS is taking an industry-leading step by formally submitting its targets to the Science-Based Target Initiative (SBTi) for validation in 2024. How will USCS get there? Cook identifies five key areas of activity and focus involving both how USCS invests in its own infrastructure as well as how it intelligently sources renewable energy inputs.

These steps include:

-

Ongoing investment in building and energy efficiency practices, technologies, and innovations

-

Continued development of on-site renewable infrastructure and energy storage capabilities.

Cook notes, for example, that the more USCS can generate its own power, the more it reduces stress on local electricity grids and establishes even more reliable energy at USCS warehouses.

Smarter buying practices include procuring renewable electricity via Power Purchase Agreement (PPA) contracts. These effectively underwrite renewable energy generation and expansion and lead to an overall “greener” power grid. USCS will also procure utility supplied renewable electricity offered through utility programs called Green Tariffs.

Finally, it also plans to buy renewable electricity attributes or certificates (RECs) to offset any remaining USCS green energy and GHG reduction needs. These voluntary markets in the US offer companies a way to invest in renewable electricity generation in a scalable manner. Looking back, USCS’s sustainability story involves more than two decades of support from its parent, John Swire & Sons.

It was more than 20 years ago that USCS focused on warehouse energy efficiency with investments in lighting efficiency, advanced refrigeration controls, variable frequency drives, and highspeed refrigerated doors. In 2007, USCS installed its first roof top solar array at its Tulare, CA, warehouse. These renewable power efforts reflect planning for on-site resiliency and emission reduction.

Since then, John Swire & Sons has created the architecture for USCS to engage in renewable electricity procurement opportunities. “The GEP outlines our pathway to leveraging all these solutions in a way that enables company resilience, growth, and performance,” says Cook. “This is all in keeping with USCS’s ‘Best-in-Cold’ approach.”

Name Says it All

USCS’s new SmartMove platform a “game changer” for LTL load planning.

The adage that “less is more” extols the virtues of simplicity. Then again, United States Cold Storage puts its own twist on the phrase. A new SmartMove program for lessthan-truckload (LTL) shipping promises more benefits for both Cold Crew team members and customers alike. And ultimately, it was a simple move—soliciting direct input from USCS load planners—that led to a breakthrough.

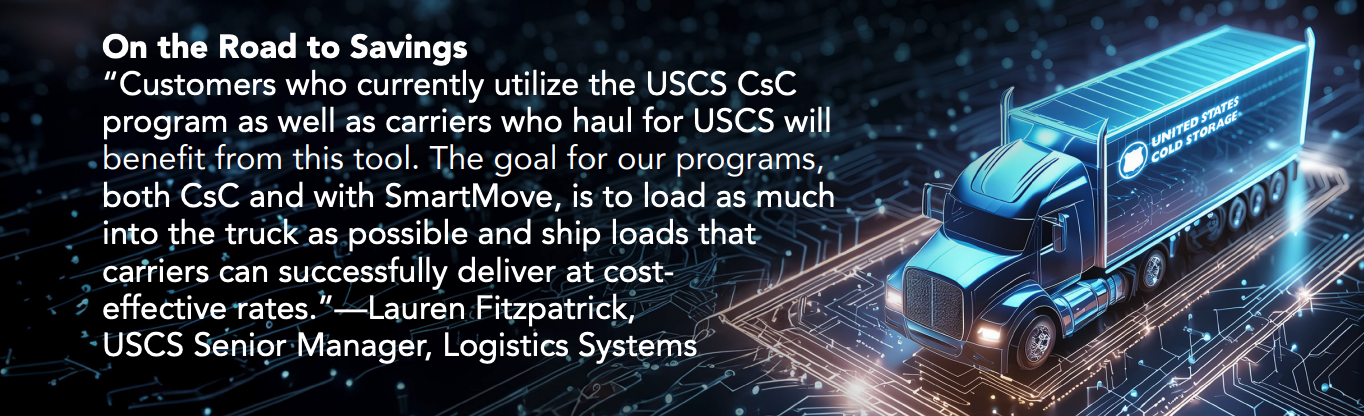

USCS Logistics’ COLDshare Consolidation (CsC) combines smaller customer orders— all headed to the same destination—into the same truck. This provides LTL customer savings because processors effectively share the total cost of the truck with others headed to the same or nearby locations. USCS Automation & Logistics Analytics Supervisor Luis Sanchez says USCS’s new SmartMove taps greater levels of information than is feasible for any one person to process.

It leverages and applies artificial intelligence to a mixture of data points— such as real-time traffic information—to select the optimal route after testing hundreds of thousands of different load combinations. “Load building optimization tools have been a challenge for the transportation industry for many years,” notes Keith Mowery, Executive Vice President, Logistics & West Region.

It leverages and applies artificial intelligence to a mixture of data points— such as real-time traffic information—to select the optimal route after testing hundreds of thousands of different load combinations. “Load building optimization tools have been a challenge for the transportation industry for many years,” notes Keith Mowery, Executive Vice President, Logistics & West Region.

“Although they integrate various data points to build loads, they traditionally have been very rigid, where the ‘rules’ set applied to all shipments. For example, the trucks traveled the same miles per hour—no matter if the load was delivering in a major metropolitan market or traveling across an interstate highway. And in the traditional scenario, all deliveries took the same amount of time to deliver. Users know that this not true in the real world, so getting buy-in from the planners who built loads was very difficult.”

He notes, “SmartMove is able to build much better loads that take into account the uniqueness of the shipment. Based on historical data, it takes into account the unloading time at that delivery point, based on time of day and size of shipment. Additionally, it is able to consider traffic conditions and even potential weather impact. Because of this flexibility and constant evolution, users are trusting the loads being built and have bought into this project.”

Luis Sanchez has developed and piloted SmartMove from April 2023 through February 2024. He credits USCS load planners for the new tool. “We focused heavily on building a userfriendly platform for load planners by truly listening to their feedback. We like to say that the platform was ‘built by load planners for load planners’ because it was so heavily inspired by the feedback we received. Even the ‘SmartMove’ name was suggested by a load planner! SmartMove is the first time we’ve been able to fully take advantage all of the different data points we can access.”

Luis Sanchez has developed and piloted SmartMove from April 2023 through February 2024. He credits USCS load planners for the new tool. “We focused heavily on building a userfriendly platform for load planners by truly listening to their feedback. We like to say that the platform was ‘built by load planners for load planners’ because it was so heavily inspired by the feedback we received. Even the ‘SmartMove’ name was suggested by a load planner! SmartMove is the first time we’ve been able to fully take advantage all of the different data points we can access.”

Lauren Fitzpatrick, Senior Manager, Logistics Systems, shares a few insights from USCS’s process. “In earlier versions, the optimization software still had to be manually fine tuned to work,” she says. “It required constant maintenance and monitoring. In contrast, SmartMove integrates historical data and automatically brings that into consideration—even with finer points, such as dwell time.” She adds, “Other optimization tools didn’t empower endusers to decide what they liked and what they didn’t like.

Ultimately, I think we achieved better buy-in by allowing our load coordinators to have full control over the process. They still make the call and can give feedback about why something didn’t work, which we can later incorporate back into the model. With these types of improvements, we have been able to find a balance between efficiency and reality.” Instant Benefits, More to Come Sanchez says USCS already has improved its on-time delivery rate with SmartMove. Moreover, he says the platform lets load planners become more proactive problem solvers.

Ultimately, I think we achieved better buy-in by allowing our load coordinators to have full control over the process. They still make the call and can give feedback about why something didn’t work, which we can later incorporate back into the model. With these types of improvements, we have been able to find a balance between efficiency and reality.” Instant Benefits, More to Come Sanchez says USCS already has improved its on-time delivery rate with SmartMove. Moreover, he says the platform lets load planners become more proactive problem solvers.

“This allows load planners to focus on what truly matters: servicing customers and ensuring that when issues inevitably arise, we can quickly resolve them.”

Looking ahead, Sanchez says USCS is incorporating SmartMove into its internal reporting so logistics reps can better help customers see how their deliveries are managed and optimized. Sanchez adds that USCS would like to further automate scheduling and carrier selection—all with a focus on reducing risk— when making any one shipment.

“I want to thank Luis and Logistics Continuous Improvement Specialist Reiner Scherzinger for their work during the past year,” Mowery concludes. “They traveled across the country to get feedback from users and coordinated our building of this tool, which is a game changer for our COLDshare program. We have increased truck utilization, which means there are fewer trucks on the road, and we have improved on-time service. This will ensure we continue to control costs for our customers while providing a sustainable solution for years to come.”

Learn more about how SmartMove powers our COLDshare Consolidation Program

Eyes on the Prize

New Vice President of Technology Bobby Kareer casts vision for USCS’s growing Center of Digital Excellence.

There are moments when professional success and personal achievement require eyes on the prize—finding the right focus and casting the right vision. That’s certainly the story of Bobby Kareer, who was promoted this April to USCS Vice President of Technology.

This story starts in December 2020 when Kareer, a software engineer, joined USCS and shifted his focus from financial investments to food. He began at USCS as Senior Director of Software and soon embraced every aspect of supply chain data management.

“It is my firm belief that software development practices and challenges transcend industry domains. However, speaking and understanding the language and priorities in the world of logistics and 3PL is something that I had to work hard at to learn and appreciate,” he says. “It helped accelerate my education by finding commonalities—such as ledger account balances and inventory balances—and the need for transparency related to how transactions (trade bookings vs. receipts/ orders) impact things.”

“It is my firm belief that software development practices and challenges transcend industry domains. However, speaking and understanding the language and priorities in the world of logistics and 3PL is something that I had to work hard at to learn and appreciate,” he says. “It helped accelerate my education by finding commonalities—such as ledger account balances and inventory balances—and the need for transparency related to how transactions (trade bookings vs. receipts/ orders) impact things.”

From a broader perspective, Kareer’s arrival and new duties were ideally timed for a period of pivotal technology growth at USCS. He points to two particular areas of focus. “My first role was to help transform our software engineering practice at USCS,” he recalls. “I worked with our technology team to ‘re-shore’ our software practice to Camden (from overseas) and transition our working model to become agile and quality driven. I am happy to report that three years in, our center of mass in technology crew has shifted to the US. We operate with a qualityfirst mindset and always look to get better at delivering value to the business.”

As software director, Kareer was responsible for USCS Phenix software and the company’s digital teams. In mid-2023, USCS promoted him to Senior Software Director and he assumed broader responsibilities for both the company’s product and B2B/EDI integration software groups. Looking back on last year, Kareer says one major milestone was to ensure that all new Phenix features and capabilities were covered with automated quality assurance tests. “This helps us curb the addition of new quality debt as we deliver releases on a monthly basis to our facilities,” he says.

“Additionally, our working practice also has improved to reflect key challenges through retrospective meetings. At the end of the day, we need to deliver better quality systems at a faster pace so that our facilities can operate efficiently. In turn, this leads to happier customers and partners.”

In this Cold Cast, Dr. Anna Johnson and Bobby discuss technology’s role in the cold chain, and the future of technology at USCS.

Welcome to McClellan Park

USCS gives SHIELD readers an inside look at operations within its coast-to-coast network.

With 39 warehouses nationwide, United States Cold Storage handles a wide variety of the nation’s refrigerated and frozen foods— products purchased at grocery stores and restaurant tables both here in the United States and around the world. Every day, these warehouses safely receive, store and ship a wide range of items—from vegetables to value-added seafood and ice cream to entrées. Accordingly, these USCS facilities and accompanying logistics programs accommodate everything from imports and exports to daily, nationwide shipments of less than-truckload orders. In the end, every USCS site is unique and reflects both its customer and product demands.

At USCS McClellan Park, CA, sustainability is not just an initiative— it’s a core principle. This state-of-the-art facility spans more than 14 million cubic feet and seamlessly integrates eco-friendly practices. Solar panels provide renewable energy, while ongoing fleet electrification efforts help reduce carbon emissions. These initiatives are part of a broader commitment to environmental stewardship—all to ensure the facility not only meets but also exceeds industry sustainability standards.

Strategically located strategically just 1.5 hours from San Francisco, USCS McClellan Park offers efficient distribution across California, as well as by advanced logistics solutions such as COLDshare consolidation and custom analytics. This prime location, combined with cutting-edge technology and a dedicated workforce, underscores USCS’s dedication to quality, safety, and innovation.

McClellan Park’s controlled temperature storage ranges from -20ºF to +50ºF and it accommodates a wide array of products, particularly from the bakery and plant-based sectors.

We consider our ongoing efforts in ensuring efficiency, safety, and excellence in our operations to be of the highest priority. With each challenge we face and each milestone we achieve, it becomes increasingly evident that our success is not only rooted in our individual capabilities but also in our shared commitment to excellence and teamwork.”

Steve Palefsky

General Manager, McClellan Park, CA

USCS expects by June, 2025 to complete a Phase 3 expansion and bolster McClellan Park with another 7.5 million cubic feet of storage. This growth is accompanied by a steadfast commitment to food safety, highlighted by McClellan Park’s BRCGS certification. Moreover, the McClellan facility’s organic certification and innovative freezing technologies (including quick freezing) offer clients unparalleled service and reliability.

Freight Consolidation

US Cold’s COLDshare Consolidation gives food producers an efficient, reliable solution.

Our consolidation services promise not just savings, but also precision in every delivery. Experience the dual benefits of financial savings and logistical precision with COLDshare Consolidation.

Innovative Technology

CsC uses SmartMove, an AI load builder making significant gains in efficiency compared to other LTL providers.

Access to Major Retailers

US Cold’s CsC has regularly scheduled appointments with the large chains in major US markets.

Streamlined Operations

Optimize your operations and maximize productivity with our solutions tailored to your specific needs.

Cost-Efficient Solutions

Reduce expenses and increase profitability with our cost-effective strategies and services.

Carrier Management

Quality control and ongoing qualification programs ensure you use top-rated drivers.

Scalable Solutions

Grow your business confidently with solutions that scale seamlessly to accommodate your evolving needs.

Reliability and Consistency

Rely on our dependable services and consistent performance to meet your logistical demands.

Customization and Flexibility

Tailor-made solutions that adapt to your unique requirements, offering flexibility and agility in every aspect of your operations.

Sustainability Focus

Embrace sustainability and environmental responsibility with eco-friendly practices and solutions that reduce your carbon footprint.

Nationwide Reach, Local Expertise

We offer coast-to-coast consolidation solution while catering to your specific regional requirements.

To redefine your shipping strategy for the better, complete the form below and our team will reach out to you: