A message from our President & CEO, Larry Alderfer

Dear Valued Customers, Colleagues, and Cold Chain Partners,

Dear Valued Customers, Colleagues, and Cold Chain Partners,

I hope this message finds you in good health and high spirits as we close out this very busy summer season. I want to take a moment to express my sincere appreciation to all our great customers, from coast to coast, and share some thoughts about our continued unrelenting ‘Best in Cold’ journey serving and supporting the cold chain.

Celebrating Our Progress

The past few months have been a rewarding period, marked by significant milestones and celebratory moments, emphasizing the remarkable commitment of our team and the invaluable support of our valued customers.

Several standout moments from this quarter are our engagement in the Warehouse of the Year competitions. Our US Cold facilities in Covington, TN, and Hazleton, PA, received prestigious awards for their outstanding performance, recognized by both Unilever and Gorton’s. These accolades are not mere tokens of appreciation; they symbolize the unwavering dedication and tireless efforts our teams invest in guaranteeing the highest level of care for our customers’ products and services to their customers.

I would also like to express my gratitude to our customers who support these programs. They not only engage our Cold Crew but also provide a clear focus on key metrics that create opportunities to drive our commitment to exceptional service. These programs also provide for deeper levels of communication and interaction throughout our organization. These engagements foster so many wonderful relationships that transcend “business as usual” driving combined innovation and the continual pursuit of service excellence and success.

The Strength of Our Connections

Our journey has been defined by strong and lasting customer relationships, and I want to extend my gratitude for the bonds we’ve formed together. Our partnership with so many of our customers spans decades and serves as a testament to the values of trust, collaboration, and mutual growth we all achieve and represent. Thank you.

Throughout this summer, I have also had the privilege of witnessing the commitment of our Cold Crew, celebrating career milestones, and enjoying the conviviality that describes our culture. We’ve had numerous team members commemorating 5, 10, and even 20 years at US Cold. I am particularly proud to acknowledge Tracy DeAnda, who is marking an impressive 40 years with our company. Her path from a Customer Service Representative to Customer Service Supervisor, and ultimately to Operations Manager is nothing short of inspirational. Tracy embodies the opportunities available at US Cold and serves as an inspiration to us all.

A Bittersweet Farewell — Rod Noll’s Retirement

Before I conclude, there is a bittersweet announcement I wish to share. Rod Noll, SVP Western Region, an absolute legend, will be transitioning to his retirement journey at the end of this year. His 42-year career with us has been extraordinary, and his influence on our business, especially in the Western region, is immeasurable. Rod’s secret to success?

Before I conclude, there is a bittersweet announcement I wish to share. Rod Noll, SVP Western Region, an absolute legend, will be transitioning to his retirement journey at the end of this year. His 42-year career with us has been extraordinary, and his influence on our business, especially in the Western region, is immeasurable. Rod’s secret to success?

His dedication to our customers and his appetite for growth. It is said that a great leader can make a decision within seven breaths; Rod captures the essence of this spirit. His contribution to our success will forever be remembered, and we wish him a well-deserved and joyful retirement.

Charting Our Course for the Future

Thanks to the support of our parent company, Swire, we continue on our fast pace of expansion. We broke ground on our new fully automated site in Lake County in Indiana, establishing operations across a 110-acre site off I-65 at Highway 2 and Colorado Street in Hebron, IN. This will be our second location in the great state of Indiana.

We’re allocating 70 acres to constructing and equipping a 13.58 million-cubic-foot public refrigerated warehouse, along with associated trailer drop areas, a dock, and COLDshare Consolidation services while reserving 40 acres for a potential customer to build an adjacent production facility in the coming years.

Once complete, the facility will house more than 43,400 pallet positions, including approximately 35,600 positions serviced by an automated storage and retrieval system and about 7,700 positions with our multifarious automation technology.

We plan to install a solar array that will provide 100% renewable energy to the warehouse, enabling UCSC to continue on our path to using 100% renewable energy by 2030.

In conclusion, I wish to convey my heartfelt appreciation to our cherished customers. Your unyielding trust, invaluable partnership, and belief in our mission of service have consistently supported the path of our journey to always be “Best in Cold.”

Larry Alderfer | President & CEO

Lead by Example

USCS supports ‘FRIDGE” Act legislation for cold chain in emerging markets.

Industry leaders distinguish themselves in many obvious ways–by size, innovation, acquisitions, or influence. On other occasions, they demonstrate it behind the scenes and support the right causes for the right reasons. Sometimes this means more time spent in Washington, D.C., than in a warehouse.

USCS executives took active roles in the Global Cold Chain Alliance (GCCA) Policy Forum this June, just before bi-partisan legislative efforts in July for the Fortifying Refrigeration Infrastructure and Developing Global Exports (FRIDGE) Act.

“One of the largest limiting factors to growing export markets for frozen and refrigerated food and agriculture products is insufficient cold chain capacity in developing countries,” says Lowell Randel, GCCA Senior Vice President of Government and Legal Affairs. “GCCA saw an opportunity to address this challenge through the Farm Bill that is up for reauthorization in 2023 and we drafted a legislative proposal that has now become the FRIDGE Act.”

He continues, “The FRIDGE Act would strengthen USDA’s trade programs by adding a focus on building the global food supply chain for frozen and refrigerated products. The Act will help GCCA members such as USCS open new markets for the products they store and distribute. Improved cold chain capacity also will help reduce food loss and waste and improve food security and nutrition in emerging markets. USCS played a prominent role in GCCA’s Policy Forum in June and actively participated in meetings with key congressional offices to build support for the FRIDGE Act.”

The FRIDGE Act was introduced as H.R. 4612 in early July by Reps. Randy Feenstra (R-IA), Tracey Mann (R-KS), James Costa (D-

CA) and Salud Carbajal (D-CA). Presenting the bill to the Senate were Mike Braun (R-IN) and John Fetterman (D-PA). Senator Braun also toured USCS’ Lebanon, IN, warehouse this summer and met with General Manager Adam Ashley.

According to the U.S. International Trade Administration, cold chain systems are crucial to the growth of global trade in perishable products and to the worldwide availability of food.

Each year, billions of tons of perishable food products and millions of dollars worth of U.S. exports are lost due to poor cold chain systems in developing markets. Increased investments in cold chain capacity will also help to decrease the more than one billion metric tons of global food waste created every year. Many of these losses result from a lack of proper facilities, improper food safety handling procedures, and insufficient training for those personnel working in the cold chain.

SUPPORT THE FRIDGE ACT

Contact your Senators and Representatives to focus efforts on improving cold chain infrastructure in developing markets.

Milestone Moment

USCS Tracy celebrates Tracy DeAnda’s 40th work anniversary.

USCS Tracy, CA, hosted a surprise luncheon and formal dinner to celebrate the 40th work anniversary of Operations Manager Tracy DeAnda. Also on hand to celebrate the event was USCS President & CEO Larry Alderfer, who first worked with DeAnda at USCS Union City, CA.

USCS Tracy, CA, hosted a surprise luncheon and formal dinner to celebrate the 40th work anniversary of Operations Manager Tracy DeAnda. Also on hand to celebrate the event was USCS President & CEO Larry Alderfer, who first worked with DeAnda at USCS Union City, CA.

“Anyone who knows Tracy, knows she is a true legend,” notes Tamara Palefsky, Continuous Improvement Manager, Western Region. “She helped us roll out our original warehouse management system and spent years as a Customer Service Manager to give our customers the best service and solutions possible.

She has a hunger to learn and more recently has expanded into operations as an Operations Manager. We are so proud to work with her and hope she’s around for another 40 years!”

Quite a Catch!

USCS Hazleton, PA, earns successive wins as “Gorton’s Warehouse of the Year”

Usually, the best fish stories involve “the one that got away. Yet here’s a case of landing that big trophy fish (or at least the trophy) in the net.

This summer saw frozen seafood leader Gorton’s present its annual 2022-2023 “Warehouse of the Year” award to USCS Hazleton, PA. Importantly, it marked the second successive win for Hazleton, which also captured Gorton’s top honors for their outstanding 2021- 2022 warehouse performance. Nationwide, Gorton’s works with eight public refrigerated warehouse partners (including five USCS locations).

Hazleton has won the award six times with performance against eight to 10 “hard” key performance indicators (such as shipping errors, and inbound and outbound loading times) as well as additional “soft” evaluations. These consider the sense of urgency, the quality and timeliness of communication and the ability to formulate and execute creative solutions to problems and urgent situations.

Hazleton has won the award six times with performance against eight to 10 “hard” key performance indicators (such as shipping errors, and inbound and outbound loading times) as well as additional “soft” evaluations. These consider the sense of urgency, the quality and timeliness of communication and the ability to formulate and execute creative solutions to problems and urgent situations.

“General Managers will tell you that our program is pretty tough, and their teams work hard to perform to our high standards,” admits Nicole Black, Gorton’s Senior Fulfillment and warehousing Manager. “With the field of players in the warehousing industry, the importance of customer service and the ability and willingness to truly partner with us to deliver the best service to our customers–can’t be overstated.” Black also talks about Hazleton’s successive wins. “Coming slowly out of the pandemic, our 2021-2022 sales continued to grow, and like so many manufacturing companies, we faced several challenges due to the ongoing supply chain disruptions,” she recalls.

“The Hazleton team consistently executed at a high level, and the proactive communication that Customer Service Representative Shannan Ford provided was top-notch. Solid execution and reliable, accurate communication were key. Our case fill rates were not perfect during this time, but our customers knew they could count on us to communicate in a timely manner and execute creative solutions to support their business.”

Considering the period from May 2022 to June 2023, Black adds, “Things slowly started to normalize last year. Supply chain disruptions lessened, our fill rates improved, and we’ve seen more consistent order patterns with fewer customer ‘emergencies.’ Despite the pandemic-related challenges of the last three years, USCS’ Hazleton team maintained their exceptional performance. As the warehouse that services the largest percentage of our business, builds the most custom mods, and ships to many of our most demanding and sensitive retailers, this speaks volumes to their hard work and dedication. Hazleton truly has a dream team working on all facets of our business— encompassing customer service, operations and transportation.”

Considering the period from May 2022 to June 2023, Black adds, “Things slowly started to normalize last year. Supply chain disruptions lessened, our fill rates improved, and we’ve seen more consistent order patterns with fewer customer ‘emergencies.’ Despite the pandemic-related challenges of the last three years, USCS’ Hazleton team maintained their exceptional performance. As the warehouse that services the largest percentage of our business, builds the most custom mods, and ships to many of our most demanding and sensitive retailers, this speaks volumes to their hard work and dedication. Hazleton truly has a dream team working on all facets of our business— encompassing customer service, operations and transportation.”

USCS Hazleton General Manager Ryan Horvath is understandably proud of the entire team. “We are most proud of our customer service, warehouse, and transportation teams working together in conjunction with Gorton’s to not only successfully service the business but having the ability to pivot tasks accordingly to satisfy Gorton’s customer needs. We would like to thank Nicole and her group for not only effectively communicating expectations, but also ensuring we had the proper schedules and inventory levels to successfully meet demand.”

Looking back more broadly, Black says Gorton’s is pleased with its USCS relationship. “Our partnership with US Cold has grown during the last 30+ years and continues to become even stronger,” she says. “Their systems, operational processes and business practices support a high standard of excellence across all aspects of warehouse operations. They strive to be ahead of the curve on IT systems and new technologies to drive operational efficiencies. We also share a dedication to sustainability efforts, and this is an important focus area for Gorton’s. “Most of all, US Cold’s people set the company apart,” she adds. “Day in and day out, we see an impressive level of dedication from employees at all levels within the organization. Their words and actions deliver a clear message that our business matters; they care about the success of our business and how we are perceived by our own customers. For us, partnership is not just a word we use loosely when we talk about our relationship with US Cold. It’s a genuine, honest characterization of our relationship and a key component to our success.”

Future in its Sites

USCS designing “Best in Cold” features into new Hebron, IN, warehouse.

In the commercial construction world, facility expansions are somewhat commonplace. By contrast, it’s not every day that corporate engineers get to plan and design a new greenfield facility. And that’s what makes USCS’ planned new site in Hebron, IN, so remarkable.

Starting with its September 2023 groundbreaking, USCS engineers and third-party design-build partners take the first step toward a USCS operation that combines the best of cold storage design and automation. Officials expect by fall 2025 to complete this 13.6 million cubic-foot frozen public warehouse. Upon completion, it will house 43,421 pallet positions and be ready to serve a wide range of customers.

“USCS’ Hebron warehouse design is the third iteration of automated warehouse design. It incorporates lessons learned from numerous USCS automated systems and USCS’ experience in layerpick technology,” notes Michael Lynch, Senior Vice President, Engineering. “The warehouse incorporates both an automated storage and retrieval system (AS/RS) coupled with a more conventional, very narrow aisle storage section.” He adds, “The ASRS systems take technologies and lessons learned from our automated systems in Lebanon, IN, McDonough (GA) 2, and Minooka, IL.

“USCS’ Hebron warehouse design is the third iteration of automated warehouse design. It incorporates lessons learned from numerous USCS automated systems and USCS’ experience in layerpick technology,” notes Michael Lynch, Senior Vice President, Engineering. “The warehouse incorporates both an automated storage and retrieval system (AS/RS) coupled with a more conventional, very narrow aisle storage section.” He adds, “The ASRS systems take technologies and lessons learned from our automated systems in Lebanon, IN, McDonough (GA) 2, and Minooka, IL.

Meanwhile, Hebron incorporates the very narrow aisle design we used in Lake City, FL. Hebron also incorporates a semiautomated, layer-pick system already deployed at numerous USCS locations. This hybrid design should be the basis for future automated warehouses going forward.” Among those also highly involved in the Hebron site is Adam Ashley, General Manager at USCS’ automated facility in Lebanon, IN (northwest of Indianapolis). Ashley says many advantages will be designed into USCS Hebron to make it …

… Worker Friendly: USCS Hebron projects to employ 42 people for a three-shift operation. One interesting benefit of automation is that it will remove warehouse associates from working in a 0°F to -5°F environment. The automated section will not have operators in the space and conventional equipment will have cabs that are able to maintain an ambient temperature.

… Driver Friendly: USCS Hebron is designed to streamline the carrier experience. All functions related to check-in and check-out processes, related paperwork and printing bills of lading will be handled at the Welcome Center (formerly guard house). Arriving drivers will be directed to the appropriate door or staging area, product will be loaded or unloaded and then the driver will be directed back to the Welcome Center to retrieve appropriate paperwork. Drivers will not have to leave their trucks if they choose not to. In addition, the Hebron site will utilize and have a dedicated lane for a new check-in process provided by Vector (similar to TSA Pre-Check). This will minimize wait times at the Welcome Center.

… Product Friendly: Products will be received on a refrigerated dock, placed on automated conveyors and directed into the warehouse; and when loading, product will be brought to the dock and placed on the trailers. This will greatly reduce dwell time on the dock for frozen products. There will be four induct locations for receiving products with each location being able to receive one truck. There are three loading zones with each zone being able to queue 58 pallets to load two trucks. … Customer Friendly: Positioned just southeast of Chicago, the Hebron warehouse helps USCS enhance its frozen COLDshare Consolidation (CsC) program with less-than-truckload savings for processor-shipper customers. Hebron is within 65 miles of sister operations in Wilmington and Minooka, IL, and within 100 miles of USCS Lebanon, IN (northwest of Indianapolis). Hebron’s location allows USCS to coordinate shipments to maximize the density of trucks that go through USCS’ CsC program.

Same Leader, New Look

USCS’ new website dramatically expands.

Think about it. In today’s rapidly evolving technological landscape, experts estimate that computer speeds and processing power double every one and a half to two years. This staggering pace of change has profound implications, particularly for corporate websites. To remain relevant and effective, these digital gateways must continuously adapt, becoming more multidimensional and interactive. One company that has recognized and embraced this imperative is United States Cold Storage (USCS), which recently unveiled a major website overhaul–its first in eight years.

The revamped USCS website has undergone a remarkable transformation, aligning itself with an evolving business environment. It boasts a sophisticated navigation bar, featuring up to seven core informational “pillars” that serve as the foundation for a more informative and engaging user experience. These pillars encompass Company, People (executive leadership), Facilities, Logistics, Technology, Communications, and Careers. Let’s delve deeper into the enhancements that USCS has introduced to cater to its existing clients, partners, prospects, and job seekers.

ENHANCEMENTS FOR CLIENTS & PARTNERS

Customer Friendly: USCS already prides itself on eUSCOLD, a proprietary, secure customer relationship management (CRM) portal that provides real-time access to inventory status and order tracking across the entire enterprise. The new website takes user-friendliness to the next level, offering seamless access to eUSCOLD while extending additional support to customers who may not be using the CRM system.

Partner Friendly: USCS has a proven track record as a reliable partner to carriers and other affiliated industry companies. The website now simplifies the process for new carriers to join the ranks of preferred partners by allowing them to apply directly on uscold.com.

Partner Friendly: USCS has a proven track record as a reliable partner to carriers and other affiliated industry companies. The website now simplifies the process for new carriers to join the ranks of preferred partners by allowing them to apply directly on uscold.com.

Cyber Secure: As a repository of real-time information and critical inventory data, USCS’s website has been fortified with multiple layers of state-of-the-art cyber protections. Ensuring the utmost security has become paramount in an era where cyber threats loom large.

A Logistics Focus: USCS’s website offers expanded coverage of the company’s logistics services, including COLDshare Consolidation, dedicated carriers, and COMPLETE, a 4pl solution. The COMPLETE service effectively functions as a manufacturer’s logistics department, expertly managing all aspects of a customer’s logistics and transportation efforts, including transportation-related reporting.

APPEALING TO PROSPECTIVE NEW PARTNERS

Easier to Find USCS: Leveraging the expertise of its digital media specialists, USCS has conducted an in-depth analysis of search engine platforms like Google and Yahoo. The goal is to better understand the keywords and terms used by prospective clients when searching for temperature-controlled warehousing, logistics, or shipping services. The specialists are working diligently to enhance USCS’s online profile, ensuring that it appears at the top or near the top of search results, making it easier for potential clients to discover the company and our 42 locations from coast to coast.

Easier to Find USCS, Part II: The website’s improved speed and enhanced capabilities allow it to swiftly display a comprehensive coast-to-coast map of USCS warehouse locations. Visitors can now access a wealth of information about each site, including geographical advantages, size, storage capacity, services offered, and contact details.

A ROBUST CAREER HUB

The career section is a dynamic hub designed to engage both internal and external job seekers effectively. The great employment benefits offered at USCS are prominently displayed, along with videos that capture the company culture and family-like atmosphere that have become a clear differentiator to those who are looking for more than just a job. Candidates benefit from clear application instructions and an online portal, along with comprehensive information on career development opportunities that underscores the company’s commitment to employee wellbeing and growth.

MORE INFORMATION, MORE WAYS

Recognizing the diverse preferences of its audience, USCS’s new website offers visitors multiple avenues to explore related company news. This includes informative videos, ColdCast podcasts, and an expanded presence on social media platforms such as LinkedIn and YouTube.

These platforms offer USCS more opportunities to share its thought leadership and highlight the expertise of its individual executives. In conclusion, USCS’s website upgrade is a testament to its commitment to innovation and client-centricity in an era of rapid technological advancement. By embracing the need for constant evolution and adopting cutting-edge cybersecurity measures, USCS is poised to provide an enhanced, user-friendly digital experience. As the pace of technological change continues unabated, USCS stands ready to meet the challenges of the future head-on, ensuring that its online presence remains at the forefront of the industry.

USCS anticipates the unveiling of the new site this October — it is a digital transformation that promises innovation, accessibility, and a richer user experience for all.

USCS Sets New Industry Standard

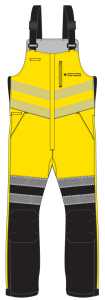

New custom freezer gear boasts added function, fashion.

In architectural design, the guiding adage is that “form follows function.” Interestingly enough, that also applies to the world of extreme cold weather gear–and you could add a measure of fashion, as well. This summer finds USCS rolling out a year-long, companywide refresh of freezer clothing for warehouse dock workers, reach drivers, leads, supervisors, inventory control personnel and visitors. It’s the first such overhaul in about five years and a crossfunctional USCS team helped guide some custom, exclusive clothing designs and features from RefrigiWear, the company’s longtime supplier. “There have been advances in freezer gear technology and features so we felt it was a good time to re-evaluate,” says Brian Murphy, USCS Senior Manager of Strategic Procurement. “The new gear will be more fashionable and functional, while it maintains the same level of warmth and protection. It also will meet ANSI 3 safety standards.”

In architectural design, the guiding adage is that “form follows function.” Interestingly enough, that also applies to the world of extreme cold weather gear–and you could add a measure of fashion, as well. This summer finds USCS rolling out a year-long, companywide refresh of freezer clothing for warehouse dock workers, reach drivers, leads, supervisors, inventory control personnel and visitors. It’s the first such overhaul in about five years and a crossfunctional USCS team helped guide some custom, exclusive clothing designs and features from RefrigiWear, the company’s longtime supplier. “There have been advances in freezer gear technology and features so we felt it was a good time to re-evaluate,” says Brian Murphy, USCS Senior Manager of Strategic Procurement. “The new gear will be more fashionable and functional, while it maintains the same level of warmth and protection. It also will meet ANSI 3 safety standards.”

Murphy led an eight-person, multifunctional group that reviewed aspects of comfort, safety and visual appeal. The committee included senior and departmental representatives from corporate development, safety, operations and even marketing. Its process included worker surveys and a focus group study for workers’ recommended improvements. For his part, Murphy acknowledges USCS Marketing Coordinator Dominica Veneziano as a lead point person for the project. He likewise credits Lisa Battino Vice President, Regulatory Compliance & Safety, for recommending that USCS embrace the industry’s latest ANSI Class 3 safety standards for freezer gear.

Here’s a review of the freezer gear program and its benefits:

Here’s a review of the freezer gear program and its benefits:

Form: USCS’ freezer gear update will involve all branded jackets, bibs and sweatshirts. This new clothing is custom designed for USCS and will not be sold to any other RefrigiWear customers.

Function: New gear, comfort rated to -40°F, has several improvements that reflect wearer recommendations. Enhancements include… … more reflective trim and high-visibility features that meet ANSI Class 3 safety standards … bib straps with a more secure closing mechanism for a better fit … hand-warmer pockets for improved comfort and warmth … radio clips with better placement, improved efficiency … badge holder on sleeve for improved efficiency, convenience.

Fashion: “Workers will appreciate the additional features and safety–all with the same consistent level of RefrigiWear quality,” notes Murphy. “We have also added a feature involving fabric, stickon patches for employee recognition. Patches can recognize individual or group achievements and there is space on each arm for recognition.” “USCS already has the reputation as ‘Best in Cold’ and this freezer gear upgrade will make it more visibly obvious that we stand out from the competition,” says Murphy. “We take pride in US Cold and we can wear this new gear in pride as well.”

Fashion: “Workers will appreciate the additional features and safety–all with the same consistent level of RefrigiWear quality,” notes Murphy. “We have also added a feature involving fabric, stickon patches for employee recognition. Patches can recognize individual or group achievements and there is space on each arm for recognition.” “USCS already has the reputation as ‘Best in Cold’ and this freezer gear upgrade will make it more visibly obvious that we stand out from the competition,” says Murphy. “We take pride in US Cold and we can wear this new gear in pride as well.”

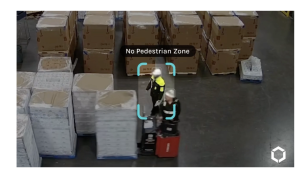

Where Technique Meets Tech

USCS uses multiple technologies to improve, enhance worker safety.

The common admonition is to work smarter–not harder. And that’s exactly what USCS strives for in protecting its most important asset, it’s employees. For the past several years, the company has invested in and implemented as many as five new technologies to better train and protect employees serving in the most demanding warehouse environments.

“Technology is changing the world of safety and USCS is a leader when it comes to creating a safe workplace,” says Lisa Battino, CSP, USCS Vice President of Compliance & Safety. “It’s important that we invest in these technologies to advance our safety journey to the next level and remain Best in Safety.” “Without US Cold employees, you don’t have US Cold Storage,” adds Ian Toomey, USCS Corporate Health and Safety Specialist.

“Technology is changing the world of safety and USCS is a leader when it comes to creating a safe workplace,” says Lisa Battino, CSP, USCS Vice President of Compliance & Safety. “It’s important that we invest in these technologies to advance our safety journey to the next level and remain Best in Safety.” “Without US Cold employees, you don’t have US Cold Storage,” adds Ian Toomey, USCS Corporate Health and Safety Specialist.

“It is our top priority to keep our employees safe and ensure that they make it home to their families. And as US Cold grows and expands, safety needs to grow and expand. This means we continue to branch out and looking for new technologies that help our warehouses continuously improve.”

Toomey identifies five technologies utilized at various warehouses throughout USCS’ network. They include two wearable applications StrongArm and Modjoul–as well as forklift monitors iWarehouse and Infolink. A fifth technology, VOXEL, is a newer artificial intelligence based software to more broadly monitor ergonomics, area controls, personal protective equipment and vehicles.

Here’s how Toomey describes each technology and its benefits.

TECH: VOXEL

How it Works: Voxel is an artificial intelligence software that pairs with existing camera systems at USCS warehouses. It absorbs hours of video feed, analyzes it, and produces real-time data. The tech simply involves one small box that plugs into the server-camera room at a US Cold location. USCS safety managers use an online VOXEL platform and dashboard to later coach employees.

How it Benefits USCS: “Each USCS location uses VOXEL in different ways. However, within a few weeks of using the technology, US Cold sites noticed safety violations or unsafe acts that managers were previously unaware of,” says Toomey. “This allowed sites to make improvements to already existing processes, and develop new safe work practices. Some of the most common items USCS monitors are missing personal protective equipment, spills, ergonomics (correct lifting posture), and forklift piggybacking (where two forklifts follow right behind one another going through a door).”

Where Utilized: Laredo, TX; West Syracuse, UT; Quakertown and Bethlehem, PA; Wilmington, IL

Tech: StrongArm

How it Works: An employee wears this like a small backpack. It targets ergonomics and correct lifting habits and it tracks individual movements. New hires wear this during their first few weeks and collected data help onsite managers better coach those employees on proper case lifting and pallet stacking.

How it Benefits USCS: This training aide reinforces proper lifting techniques.

Where Utilized: Lebanon, IN, and Wilmington, IL

Tech: Modjoul

How it Works: This wearable technology goes around the waist. It is essentially a belt that gathers data related to ergonomics, temperature and forklift driver activities, among other things.

How it Benefits USCS: Modjoul data help safety experts better pinpoint where and how to train workers on lifting techniques.

Where Utilized: Dallas Halifax and Dallas Cockrell Hill, TX; Tulare South and Fresno, CA

Tune into the ColdCast

Meet Brian Murphy

Discover the interesting world of US Cold Procurement in this enlightening podcast interview with the Senior Manager of Strategic Procurement. Dive deep into the intricacies of the procurement process, unraveling its purpose and significance in today’s business landscape.

Gain insights into why procurement is the linchpin of success for any organization, and how it plays a pivotal role in shaping US Cold’s sustainability efforts. Prepare to be captivated by unexpected discoveries and revelations that emerge during the procurement journey. Broaden your understanding and unlock the secrets behind this often-overlooked but critically important facet of business operations.