welcome to

Wilmington, IL

COLD SPECIFICATIONS:

13,548,000 Cubic Feet

51,000 Racked Pallet Positions

Temps Ranging from -10ºF to +36ºF

STRATEGICALLY LOCATED:

Chicago, IL – 1 hour

Milwaukee, WI – 2 hours

Madison, WI – 3 hours

ADDRESS:

800 E. Kankakee River Drive

Wilmington, IL 60481

(815) 476-2653

David Salazar

General Manager

Welcome to US Cold Storage in Wilmington, IL!

Our facility is more than just a warehouse—it’s a fully integrated, people-driven logistics hub where innovation meets reliability. For over a decade, I’ve had the privilege of working alongside a team that sets the bar for what it means to be Best in Cold. From inventory supervisors with decades of tenure to customer service leads who know each account by heart, this team delivers with consistency, passion, and pride.

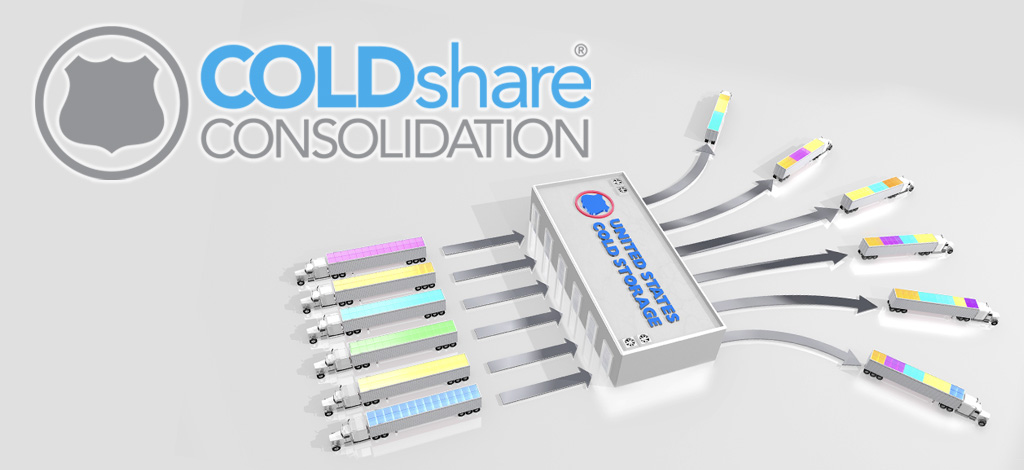

What makes Wilmington exceptional isn’t just our location or our scale. It’s the culture we’ve built—one grounded in accountability, camaraderie, and forward-thinking service. We operate the largest Cold Share Consolidation (CSC) program in the company, helping customers reduce costs, streamline operations, and shrink their carbon footprint, all while keeping food moving across all 48 states.

Our team regularly participates in community-driven initiatives and Cold Crew Cares campaigns. From Earth Day cleanups to Connect for a Cause drives, we’re proud to give back to the communities we serve.

Internally, we foster a culture of excellence. We’re early adopters of technology and safety innovations, and our track record of zero DART incidents speaks to the care we have for our people.

Add to that our 98% driver satisfaction rate and top-tier survey participation, and it’s clear that this is a facility fueled by dedication and driven by purpose.

We’re proud of the legacy we’re building here—and we’re even more excited about what lies ahead. Whether you’re looking for storage, transport, or full-service logistics solutions, we’re here to serve you with integrity, passion, and precision.

Wilmington is Best in Cold Storage

National Reach, Local Heart

Wilmington operates at a national scale while remaining deeply connected to our community. From our work with Cold Crew Cares to our employee-driven culture, we put people first—whether they’re on the floor, behind the wheel, or across the country. Our leadership and operations teams boast decades of combined experience:

> Over 32 years in inventory supervision

> Long-term tenures across customer service, engineering, and operations

> A reputation for consistent excellence and reliable relationships

> Largest consolidation program across the USA.

58 Dock Doors

Efficient loading and unloading with secure, streamlined access for the movement of goods in and out of our facility.

Export

Specialized handling and storage to maintain optimal temperatures, ensuring the products reach their international destination with their quality and freshness intact.

BRCGS Certified

Globally recognized for food safety and quality, ensuring rigorous international standards throughout the supply chain.

Repack

Efficiently and accurately reconfiguring your products into different packaging or quantities, for a completely customized shipment.

eWMS

Our eWMS solution streamlines inventory control, order processing, and distribution, enhancing efficiency and accuracy within the warehousing operations.

Layer Picking

We can pick entire layers of products, ensuring faster order processing, reduced errors, and cost savings. Orders are fulfilled with increased efficiency, accuracy, and speed.

Get a Quote for Wilmington

In Wilmington, we’re not just managing product—we’re delivering results. Strategically located in the heart of America’s logistics corridor, we service all 48 contiguous states with precision, pride, and purpose. Backed by decades of experience, cutting-edge automation, and the largest Cold Share Consolidation program in our network, this is where cold chain logistics meet elite operational execution.

Adam Ashley

Area Director

Wilmington is Best in Safety

Safety is the foundation of everything we do at Wilmington. In a high-performance, high-velocity environment like cold chain logistics, protecting our people isn’t just a responsibility, it’s essential to operational excellence.

Safety is the foundation of everything we do at Wilmington. In a high-performance, high-velocity environment like cold chain logistics, protecting our people isn’t just a responsibility, it’s essential to operational excellence.

We believe a safe facility is a successful facility, and our commitment to safety touches every corner of our operations. Here’s how we make it real every day:

Zero DART (Days Away, Restricted, or Transferred): Our current DART rate is zero, reflecting our unwavering focus on injury prevention and response readiness.

Fully Digital Safety Training: All employees complete interactive digital training modules for both initial onboarding and annual recertifications, ensuring consistent knowledge and compliance.

VOXEL Camera Systems: Our predictive safety analytics are powered by camera technology that identifies ergonomic risks and near-miss behaviors, enabling timely coaching and intervention.

Wearable Technology: Select teams are equipped with safety wearables that track motion and posture, helping reduce strain-related injuries before they happen.

Observation & Feedback Programs: Through tools like iAuditor and peer observations, we identify trends early and implement proactive safety solutions.

Culture of Accountability: Safety isn’t confined to management—it’s a shared mindset. Our team members regularly call out unsafe practices, support one another, and take pride in working safely together.

Wilmington is Sustainable

Sustainability is deeply woven into the culture at our Wilmington facility, not just as a corporate initiative, but as a personal commitment from every team member. We recognize that operational excellence must go hand in hand with environmental responsibility, which is why we’re constantly innovating to reduce our impact and lead by example in the cold storage industry.

Our sustainability efforts are designed to be practical, measurable, and enduring, supporting both our community and the planet. Here’s how we’re making it happen:

100% Renewable Electricity: Wilmington is enrolled in a green energy tariff, ensuring that all electricity used at the facility comes from renewable sources.

Elimination of Single-Use Plastics: We’ve removed Styrofoam cups, plasticware, and bottled water from our breakrooms, replacing them with ceramic mugs, reusable utensils, and hydration stations.

Water Conservation through Xeriscaping: We’re converting over 70,000 square feet of lawn into drought-tolerant landscaping, reducing water usage significantly and qualifying for state incentives.

Electric Yard Truck: Our on-site EV truck replaces traditional diesel yard equipment, reducing both emissions and fuel costs while improving operational efficiency.

Employee Engagement in Green Practices: Every team member receives reusable tools and participates in sustainable office practices, because we believe sustainability starts with small, consistent choices.

Community Environmental Action: We participate in local Earth Day clean-ups and conservation efforts, reinforcing our role as a responsible corporate citizen.

These are just a few ways our team is turning values into action, proving that being Best in Cold also means doing what’s best for the world around us.

“For us, sustainability isn’t a side project, it’s built into the way we operate every single day. From running on 100% renewable electricity to eliminating single-use plastics and investing in electric yard equipment, we’re proving that environmental responsibility and operational excellence can go hand in hand.”

– Jerry Cassidy, Operations Manager

Wilmington is Best in Automation

Innovation meets precision with the integration of our automated gantry layer picker system, the first of its kind in the US Cold network.

Designed to handle high-volume, mixed-SKU orders with speed and consistency, the gantry system allows us to streamline complex case-pick operations while reducing manual labor and error rates.

This technology enables our team to fulfill large, custom pallet builds with greater efficiency, especially for retail and foodservice customers who demand accuracy and tight turnarounds. By automating this previously labor-intensive process, we’re improving throughput, enhancing safety, and delivering a smarter, faster service experience.

Wilmington’s gantry system isn’t just a tech upgrade, it’s a strategic investment in our customers’ evolving needs and our commitment to being Best in Cold.

Wilmington is Best in COLDshare Consolidation

Wilmington is home to the most robust COLDshare Consolidation operation in the company and one of the largest in the cold chain industry. Every day, we consolidate temperature-controlled shipments from customers across the region into full truckloads, delivering to destinations from California to Florida to the Northeast.

Lower Costs: By consolidating shipments from multiple customers, we reduce linehaul, accessorial, and per-load fees.

Operational Efficiency: Fewer trucks in and out means less congestion, smoother dock operations, and better throughput.

Sustainability: Fewer trucks on the road = fewer emissions. It’s better for your business and better for the planet.

Priority Access: CSC customers benefit from streamlined shipping schedules and service-level prioritization.

True One-Stop Logistics

What makes COLDshare in Wilmington unique is its integration. Customers don’t need to coordinate warehousing and transport separately. We offer both under one roof, powered by a single team with shared goals.

COMPLETE

From raw materials to the shelf, we can optimize your supply chain so your team can focus on making and selling your product. Our 4PL is your complete logistics solution.

COLDshare Consolidation

Join our consolidation program so you can reduce your freight charges on LTL shipments. Our program is the best in the US with deliveries made across the country every day.

Custom Analytics

Get analytics tailored to your needs sent proactively to you every week. Real-time data helps you make decisions quickly and with accuracy.

Shuttle Services

Seamlessly transporting perishables, we ensure optimal temperatures, safeguarding your goods' freshness. Our fleet is tailored for reliability, rapid response, and customizable solutions.

Brokerage Services

With a vast network of reliable carriers, we craft tailored solutions for every cargo need. Our expert brokers use industry insights and cutting-edge technology to ensure timely deliveries.

Network Analytics

Streamline your logistics and maximize every node of your supply chain. At US Cold, we harmonize inventory management, reduce lead times, and minimize costs.